Specifications | Node number | Reduction ratio1 | FAD047 | FAD064 | FAD090 | FAD110 | FAD140 | FAD200 | FAD255 | |

Rated Output Moment T2N | Nm | 1 | 4 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 |

5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

2 | 20 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | ||

25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

40 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | |||

50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

16 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | |||

21 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

31 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

61 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

91 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

Maximum output Moment T2B | Nm | 1,2 | 4~100 | Three times the rated output torque | ||||||

Rated input Speed n1N | rpm | 1,2 | 4~100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

Maximum input Speed n1B | rpm | 1,2 | 4~100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

Ultra precision Back clearance P0 | arcmin | 1 | 4~10 | - | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

2 | 20~100 | - | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ||

Precision backlash P1 | arcmin | 1 | 4~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

2 | 20~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

Standard backlash P2 | arcmin | 1 | 4~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

2 | 20~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

Torsional rigidity | Nm/arcmin | 1,2 | 4~100 | 7 | 13 | 31 | 82 | 151 | 440 | 1006 |

The maximum bending Moment M2KB2 | Nm | 1,2 | 4~100 | 42.5 | 125 | 235 | 430 | 1300 | 3064 | 5900 |

Permissible To force F2B2 | N | 1,2 | 4~100 | 1080 | 2110 | 2310 | 4800 | 6200 | 5450 | 10600 |

Service life | hr | 1,2 | 4~100 | 30000* | ||||||

Efficiency η | % | 1 | 4~10 | ≥97% | ||||||

2 | 20~100 | ≥94% | ||||||||

Weight | kg | 1 | 4~10 | 0.7 | 1.2 | 3.0 | 5.6 | 11.9 | 31.6 | 56.1 |

2 | 20~100 | 1.0 | 1.6 | 3.7 | 7.3 | 15.9 | 36.9 | 70.4 | ||

16~91 | 1.0 | 1.4 | 3.5 | 6.5 | 15.5 | 34.2 | 67.2 | |||

Use temperature | °C | 1,2 | 4~100 | -10°C~+90°C | ||||||

Lubrication | 1,2 | 4~100 | Synthetic lubricating oil (NYOGEL 792D) | |||||||

Protection grade | 1,2 | 4~100 | IP65 | |||||||

Installation direction | 1,2 | 4~100 | Any direction | |||||||

Noise value(n1=3000 rpm) | dB | 1,2 | 4~100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

Specifications | Node number | Reduction ratio1 | FAD047 | FAD064 | FAD090 | FAD110 | FAD140 | FAD200 | FAD255 | |

Moment of inertiaJ1 | kg•cm2 | 1 | 4 | 0.03 | 0.14 | 0.51 | 2.87 | 7.54 | 25.03 | 58.31 |

5 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | |||

7 | 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | |||

10 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | |||

2 | 20 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | ||

25 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | |||

35 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | |||

40 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

50 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

70 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

100 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

16 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | |||

21 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | |||

31 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

61 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

91 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | |||

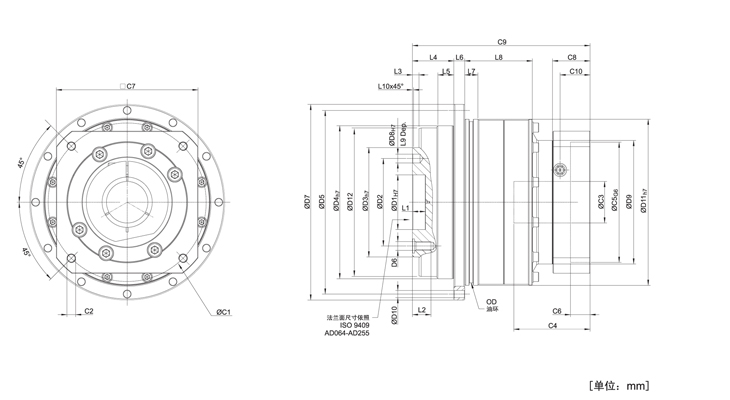

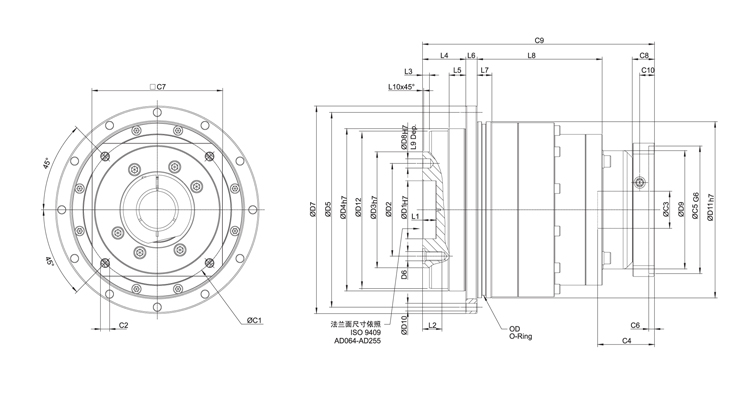

Size | FAD047 | FAD064 | FAD090 | FAD110 | FAD140 | FAD200 | FAD255 |

D1H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

D3h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

D4h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

D6 | 4xM3x0.5P | 7xM5x0.8P | 7xM6x1P | 11xM6x1P | 11xM8x1.25P | 11xM10x1.5P | 12xM16x2P |

D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

D8H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

D9 | 45.5 | 55 | 77 | 90 | 113 | 138 | 175 |

D10 | 8x3.4 | 8x4.5 | 8x5.5 | 8x5.5 | 12x6.6 | 12x9 | 16x13.5 |

D11h7 | 60 | 70 | 95 | 120 | 152 | 212 | 255 |

D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

L7 | 5 | 7.7 | 8 | 10 | 12 | 15 | 20 |

L8 | 18.5 | 28.5 | 27 | 37 | 62 | 69.5 | 82 |

L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

L10 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 |

C13 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

C23 | M4x0.7P | M5x0.8P | M6x1P | M8x1.25P | M10x1.5P | M12x1.75P | M12x1.75P |

C33 | ≤11 | *≤14/≤16 | ≤19/≤24 | ≤11 | ≤11 | ≤11 | ≤11 |

C43 | 30 | 34 | 40 | 50 | 60 | 85 | 116 |

C53G6 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

C63 | 3.5 | 8 | 4 | 5 | 6 | 6 | 6 |

C73 | 48 | 60 | 90 | 115 | 142 | 190 | 220 |

C83 | 19.5 | 19 | 17 | 19.5 | 22.5 | 29 | 63 |

C93 | 70 | 82.5 | 99.5 | 121.5 | 151 | 199.5 | 256.5 |

C103 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53.5 |

OD | 56x2 | 66x2 | 90x3 | 110x3 | 145x3 | 200x5 | 238x5 |

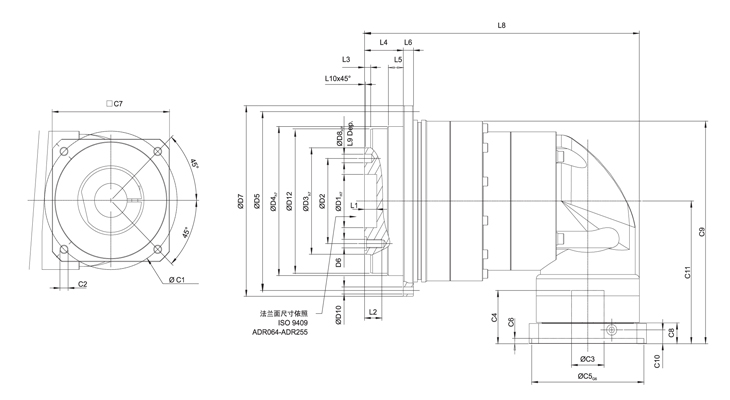

Size | FAD047 | FAD064 | FAD090 | FAD110 | FAD140 | FAD200 | FAD255 |

D1H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

D3h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

D4h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

D6 | 4xM3x0.5P | 7xM5x0.8P | 7xM6x1P | 11xM6x1P | 11xM8x1.25P | 11xM10x1.5P | 12xM16x2P |

D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

D8H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

D9 | 45.5 | 45.5 | 53.4 | 77 | 102 | 125 | 160 |

D10 | 8x3.4 | 8x4.5 | 8x5.5 | 8x5.5 | 12x6.6 | 12x9 | 16x13.5 |

D11h7 | 60 | 70 | 95 | 120 | 152 | 212 | 255 |

D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

L7 | 5 | 7.7 | 8 | 10 | 12 | 15 | 20 |

L8 | 54.5 | 65 | 60 | 87.5 | 110 | 132.5 | 148 |

L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

L10 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 |

C14 | 46 | 46 | 70 | 100 | 130 | 165 | 200 |

C24 | M4x0.7P | M4x0.7P | M5x0.8P | M6x1P | M8x1.25P | M10x1.5P | M12x1.75P |

C34 | ≤11 | *≤11/≤12 | *≤14/≤15.875/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 |

C44 | 30 | 30 | 34 | 40 | 50 | 60 | 85 |

C54G6 | 30 | 30 | 50 | 80 | 110 | 130 | 180 |

C64 | 3.5 | 3.5 | 8 | 4 | 5 | 6 | 6 |

C74 | 48 | 48 | 60 | 90 | 115 | 142 | 190 |

C84 | 19.5 | 19.5 | 19 | 17 | 19.5 | 22.5 | 29 |

C94 | 97.5 | 108 | 134 | 160 | 204 | 248 | 311.5 |

C104 | 13.25 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 |

OD | 56x2 | 66x2 | 90x3 | 110x3 | 145x3 | 200x5 | 238x5 |

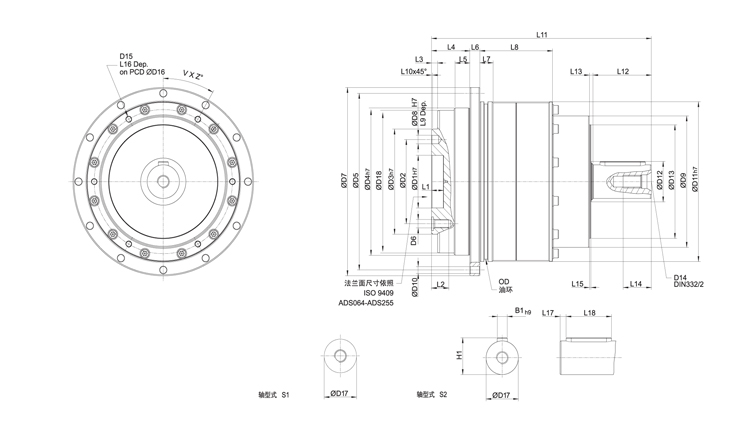

Size | FAD047 | FAD064 | FAD090 | FAD110 | FAD140 | FAD200 | FAD255 |

D1H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

D3h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

D4h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

D6 | 4xM3x0.5P | 7xM5x0.8P | 7xM6x1P | 11xM6x1P | 11xM8x1.25P | 11xM10x1.5P | 12xM16x2P |

D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

D8H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

D9 | 45.5 | 45.5 | 55 | 77 | 90 | 113 | 138 |

D10 | 8x3.4 | 8x4.5 | 8x5.5 | 8x5.5 | 12x6.6 | 12x9 | 16x13.5 |

D11h7 | 60 | 70 | 95 | 120 | 152 | 212 | 255 |

D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

L7 | 5 | 7.7 | 8 | 10 | 12 | 15 | 20 |

L8 | 52.5 | 28.5 | 32 | 37 | 122 | 79.5 | 82 |

L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

L10 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 |

C15 | 46 | 46 | 70 | 100 | 130 | 165 | 215 |

C25 | M4x0.7P | M4x0.7P | M5x0.8P | M6x1P | M8x1.25P | M10x1.5P | M12x1.75P |

C35 | ≤11 | *≤11/≤12 | *≤14/≤15.875/≤16 | ≤19/≤24 | ≤32 | ≤38 | ≤48 |

C45 | 30 | 30 | 34 | 40 | 50 | 60 | 85 |

C55G6 | 30 | 30 | 50 | 80 | 110 | 130 | 180 |

C65 | 3.5 | 3.5 | 8 | 4 | 5 | 6 | 6 |

C75 | 48 | 48 | 60 | 90 | 115 | 142 | 190 |

C85 | 19.5 | 19.5 | 19 | 17 | 19.5 | 22.5 | 29 |

C95 | 100 | 106 | 130.5 | 149 | 205 | 247.5 | 323 |

C105 | 13.25 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 |

OD | 56x2 | 66x2 | 90x3 | 110x3 | 145x3 | 200x5 | 238x5 |

Specifications | Node number | Reduction ratio1 | FADR042 | FADR060 | FADR090 | FADR115 | FADR142 | FADR180 | FADR220 | |

Rated output torqueT2N | Nm | 1 | 4 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 |

5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

14 | - | 42 | 140 | 300 | 550 | 1100 | 1800 | |||

20 | - | 40 | 100 | 230 | 450 | 900 | 1500 | |||

2 | 20 | 19 | - | - | - | - | - | - | ||

25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

40 | 19 | 48 | 130 | 270 | 560 | 1100 | 1700 | |||

50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

140 | - | - | 140 | 300 | 550 | 1100 | 1800 | |||

200 | - | - | 100 | 230 | 450 | 900 | 1500 | |||

Maximum output Moment 力矩T2B | Nm | 1,2 | 4~200 | Three times the rated output torque | ||||||

Rated output Speed n1N | rpm | 1,2 | 4~200 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

Maximum input Speed n1B | rpm | 1,2 | 4~200 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

Ultra precision Back clearance P0 | arcmin | 1 | 4~20 | - | - | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

2 | 25~200 | - | - | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ||

Precision backlash P1 | arcmin | 1 | 4~20 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 |

2 | 25~200 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

Precision backlash P2 | arcmin | 1 | 4~20 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

2 | 25~200 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ||

Torsional rigidity | Nm/arcmin | 1,2 | 4~200 | 7 | 13 | 31 | 82 | 151 | 440 | 1006 |

The maximum bending Moment M2KB2 | Nm | 1,2 | 4~200 | 42.5 | 125 | 235 | 430 | 1300 | 3064 | 5900 |

Allowable axial force F2B2 | N | 1,2 | 4~200 | 1080 | 2110 | 2310 | 4800 | 6200 | 5450 | 10600 |

Service life | hr | 1,2 | 4~200 | 30000* | ||||||

Efficiencyη | % | 1 | 4~20 | ≥95% | ||||||

2 | 25~200 | ≥92% | ||||||||

Weight | kg | 1 | 4~20 | 1.1 | 2.1 | 5.9 | 10.5 | 21.9 | 50.9 | 85.4 |

2 | 25~200 | 1.4 | 1..9 | 4.5 | 9.8 | 20.1 | 45.4 | 85.9 | ||

Use temperature | °C | 1,2 | 4~200 | -10°C~+90°C | ||||||

Lubrication | 1,2 | 4~200 | Synthetic grease(NYOGEL 792D) | |||||||

Protection grade | 1,2 | 4~200 | IP65 | |||||||

Installation direction | 1,2 | 4~200 | Any direction | |||||||

Noise value(n1=3000rpm | dB | 1,2 | 4~200 | ≤61 | ≤63 | ≤65 | ≤68 | ≤70 | ≤72 | ≤74 |

| Specifications | Node number | Reduction ratio1 | FADR047 | FADR064 | FADR090 | FADR110 | FADR140 | FADR200 | FADR255 | |

Moment of inertiaJ1 | kg•cm2 | 1 | 4~10 | 0.09 | 0.35 | 2.25 | 6.84 | 23.4 | 68.9 | 135.4 |

14 | - | 0.07 | 1.87 | 6.25 | 21.8 | 65.6 | 119.8 | |||

20 | - | 0.07 | 1.87 | 6.25 | 21.8 | 65.6 | 119.8 | |||

2 | 20 | 0.09 | - | - | - | - | - | - | ||

25~100 | 0.09 | 0.09 | 0.35 | 2.25 | 6.84 | 23.4 | 68.9 | |||

140~200 | - | - | 0.31 | 1.87 | 6.25 | 21.8 | 65.6 | |||

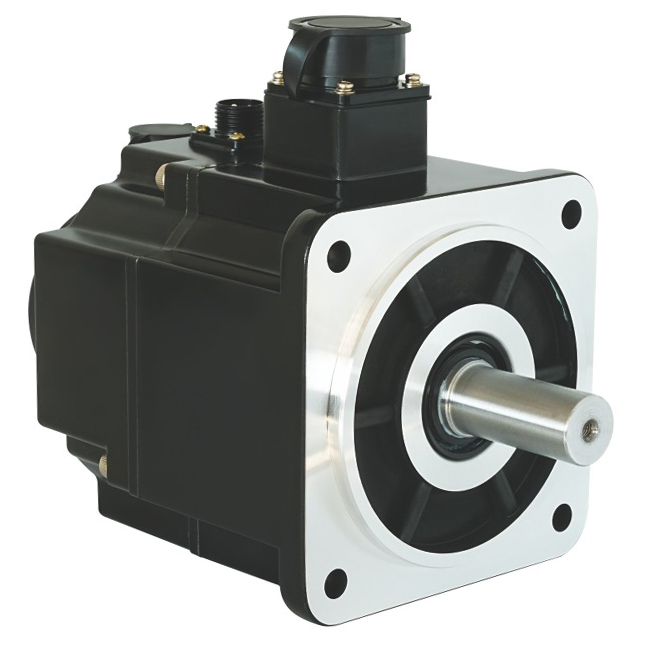

Welcome to contact us for other series ac servo motor.