Specifications | Node number | Reduction ratio | FAB042 | FAB060 | FAB060A | FAB090 | FAB 090A | FAB115 | FAB142 | FAB180 | FAB220 | |

Rated output torqueT2n | Nm | 1 | 3 | 20 | 55 | - | 130 | - | 208 | 342 | 588 | 1140 |

4 | 19 | 50 | - | 140 | - | 290 | 542 | 1050 | 1700 | |||

5 | 22 | 60 | - | 160 | - | 330 | 650 | 1200 | 2000 | |||

6 | 20 | 55 | - | 150 | - | 310 | 600 | 1100 | 1900 | |||

7 | 19 | 50 | - | 140 | - | 300 | 550 | 1100 | 1800 | |||

8 | 17 | 45 | - | 120 | - | 260 | 500 | 1000 | 1600 | |||

9 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

10 | 14 | 40 | - | 100 | - | 230 | 450 | 900 | 1500 | |||

2 | 15 | 20 | 55 | 55 | 130 | 130 | 208 | 342 | 588 | 1140 | ||

20 | 19 | 50 | 50 | 140 | 140 | 290 | 542 | 1050 | 1700 | |||

25 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

30 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

35 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

40 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

45 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

50 | 22 | 60 | 60 | 160 | 160 | 330 | 650 | 1200 | 2000 | |||

60 | 20 | 55 | 55 | 150 | 150 | 310 | 600 | 1100 | 1900 | |||

70 | 19 | 50 | 50 | 140 | 140 | 300 | 550 | 1100 | 1800 | |||

80 | 17 | 45 | 45 | 120 | 120 | 260 | 500 | 1000 | 1600 | |||

90 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

100 | 14 | 40 | 40 | 100 | 100 | 230 | 450 | 900 | 1500 | |||

The maximum output torque T2B | Nm | 1,2 | 3~100 | Three times the rated output torque | ||||||||

Rated input speed n1N | rpm | 1,2 | 3~100 | 5000 | 5000 | 5000 | 4000 | 4000 | 4000 | 3000 | 3000 | 2000 |

The input speed n1B | rpm | 1,2 | 3~100 | 10000 | 10000 | 10000 | 8000 | 8000 | 8000 | 6000 | 6000 | 4000 |

Ultra precision backlash P0 | arcmin | 1 | 3~10 | - | - | - | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

2 | 15~100 | - | - | - | - | - | ≤3 | ≤3 | ≤3 | ≤3 | ||

Precision backlash P1 | arcmin | 1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

2 | 15~100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

Standard backlash P2 | arcmin | 1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

2 | 15~100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

Torsional rigidity | Nm/arcmin | 1,2 | 3~100 | 3 | 7 | 7 | 14 | 14 | 25 | 50 | 145 | 225 |

Permissible radial force F2rB2 | N | 1,2 | 3~100 | 780 | 1530 | 1530 | 3250 | 3250 | 6700 | 9400 | 14500 | 50000 |

Allowable axial force F2a1B2 | N | 1,2 | 3~100 | 350 | 630 | 630 | 1300 | 1300 | 3000 | 4000 | 6200 | 35000 |

Allowable axial force F2a2B2 | N | 1,2 | 3~100 | 390 | 765 | 765 | 1625 | 1625 | 3350 | 4700 | 7250 | 25000 |

Service life | hr | 1,2 | 3~100 | 20000* | ||||||||

Efficiencyη | % | 1 | 3~10 | ≥97% | ||||||||

2 | 15~100 | ≥94% | ||||||||||

Weight | kg | 1 | 3~10 | 0.5 | 1.3 | - | 3.7 | - | 7.8 | 14.5 | 29 | 48 |

2 | 15~100 | 0.8 | 1.5 | 1.9 | 4.1 | 5.3 | 9 | 17.5 | 33 | 60 | ||

Use temperature | °C | 1,2 | 3~100 | -10°C~+90°C | ||||||||

Lubrication | 1,2 | 3~100 | Synthetic lubricating oil (NYOGEL 792D) | |||||||||

Protection grade | 1,2 | 3~100 | IP65 | |||||||||

Installation direction | 1,2 | 3~100 | Any direction | |||||||||

Noise valuen1=3000rpm | dB | 1,2 | 3~100 | ≤56 | ≤58 | ≤58 | ≤60 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

Specifications | Node number | Reduction ratio1 | FAB042 | FAB060 | FAB060A | FAB090 | FAB090A | FAB115 | FAB142 | FAB180 | FAB220 | |

Moment of inertiaJ1 | kg•cm2 | 1 | 3 | 0.03 | 0.16 | - | 0.61 | - | 3.25 | 9.21 | 28.98 | 69.61 |

4 | 0.03 | 0.14 | - | 0.48 | - | 2.74 | 7.54 | 23.67 | 54.37 | |||

5 | 0.03 | 0.13 | - | 0.47 | - | 2.71 | 7.42 | 23.29 | 53.27 | |||

6 | 0.03 | 0.13 | - | 0.45 | - | 2.65 | 7.25 | 22.75 | 51.72 | |||

7 | 0.03 | 0.13 | - | 0.45 | - | 2.62 | 7.14 | 22.48 | 50.97 | |||

8 | 0.03 | 0.13 | - | 0.44 | - | 2.58 | 7.07 | 22.59 | 50.84 | |||

9 | 0.03 | 0.13 | - | 0.44 | - | 2.57 | 7.04 | 22.53 | 50.63 | |||

10 | 0.03 | 0.13 | - | 0.44 | - | 2.57 | 7.03 | 22.51 | 50.56 | |||

2 | 15 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | ||

20 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |||

25 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |||

30 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |||

35 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |||

40 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |||

45 | 0.03 | 0.03 | 0.13 | 0.13 | 0.47 | 0.47 | 2.71 | 7.42 | 23.29 | |||

50 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | |||

60 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | |||

70 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | |||

80 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | |||

90 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | |||

100 | 0.03 | 0.03 | 0.13 | 0.13 | 0.44 | 0.44 | 2.57 | 7.03 | 22.51 | |||

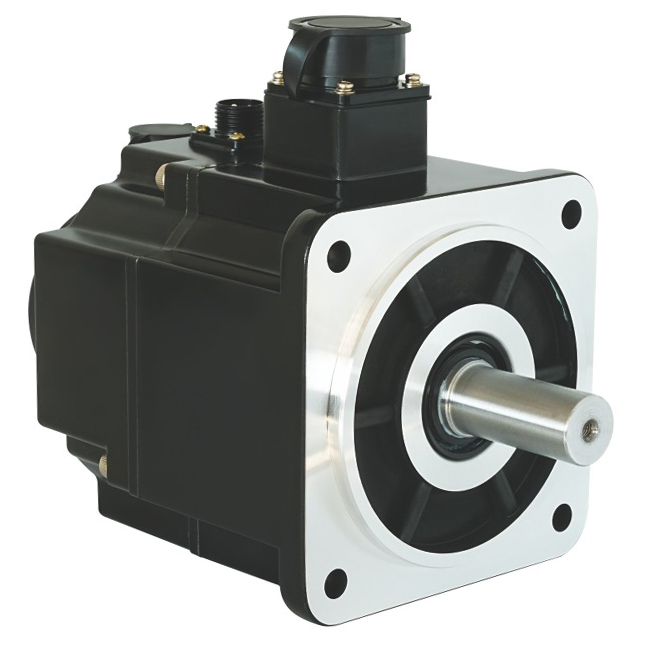

Welcome to contact us for other series ac servo motor.